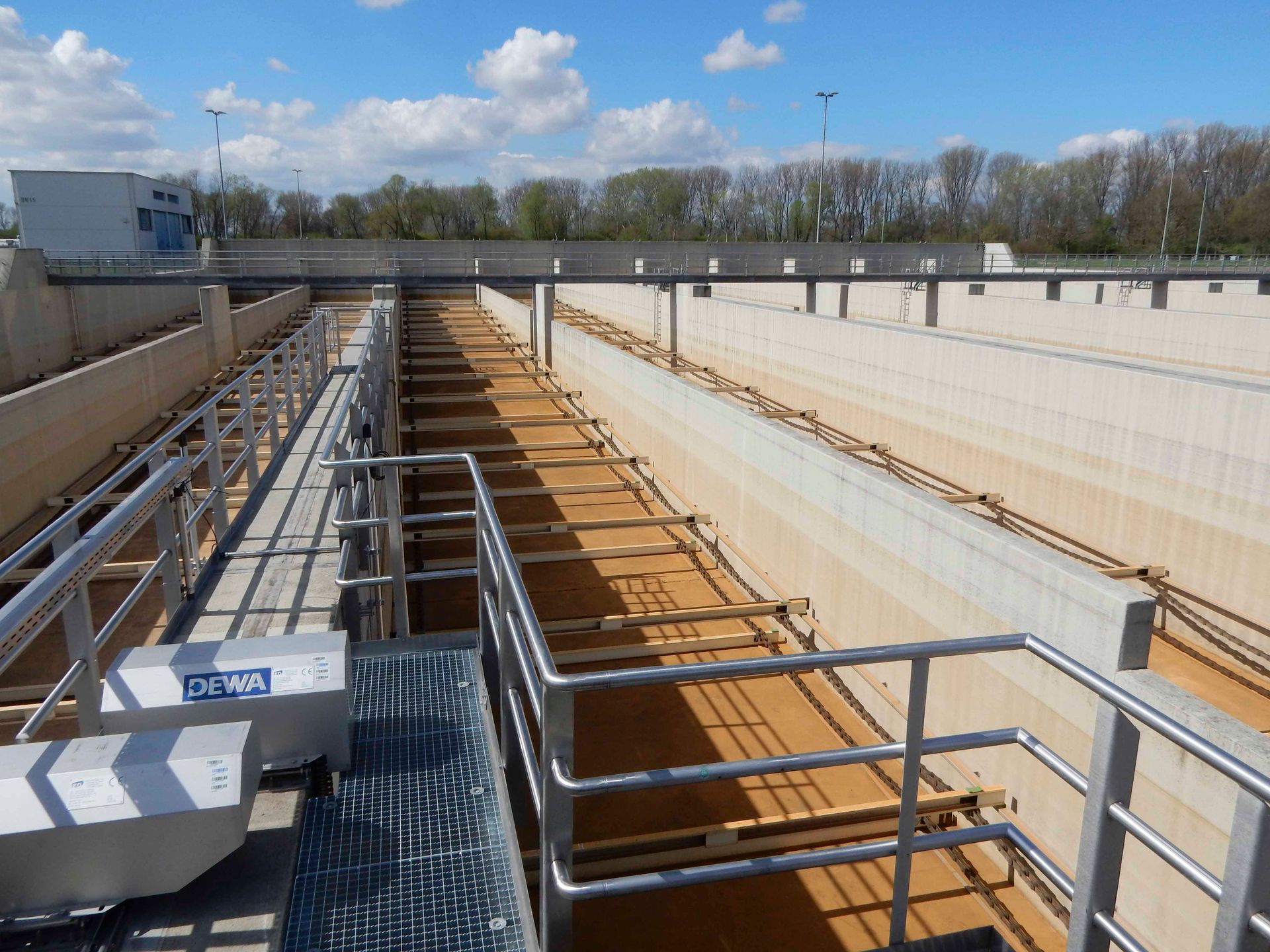

Sedimentation tank: 29 x 8,8 m

2 DEWA® Plastic chain scraper systems

As part of an expansion of the Wassmannsdorf sewage treatment plant near Berlin, we supplied and installed two DEWA® plastic chain scrapers for the two new flocculation filtration sedimentation tanks in spring 2023. The scrapers are designed as three-shaft systems for bottom sludge removal. In order to be able to monitor the scraper chain tension during operation, i.e. when the tank is full, a tension control system with compression springs and inductive sensors is used, which sends a message to the operating personnel if the chain tension is insufficient. Our running and synchronisation monitoring system serves as a monitoring device for flight misalignment and chain breakage, which switches off the system in the event of a fault. Each of our DEWA® plastic chain scrapers is also operated with an active power monitor for overload protection. Due to the positive experience with the DEWA® scrapers in the primary clarifiers, Berliner Wasserbetriebe (BWB) is also relying on proven technology here. The plant is expected to be commissioned in summer 2024.

Waste water treatment plant Berlin-Wassmannsdorf, Germany 2023

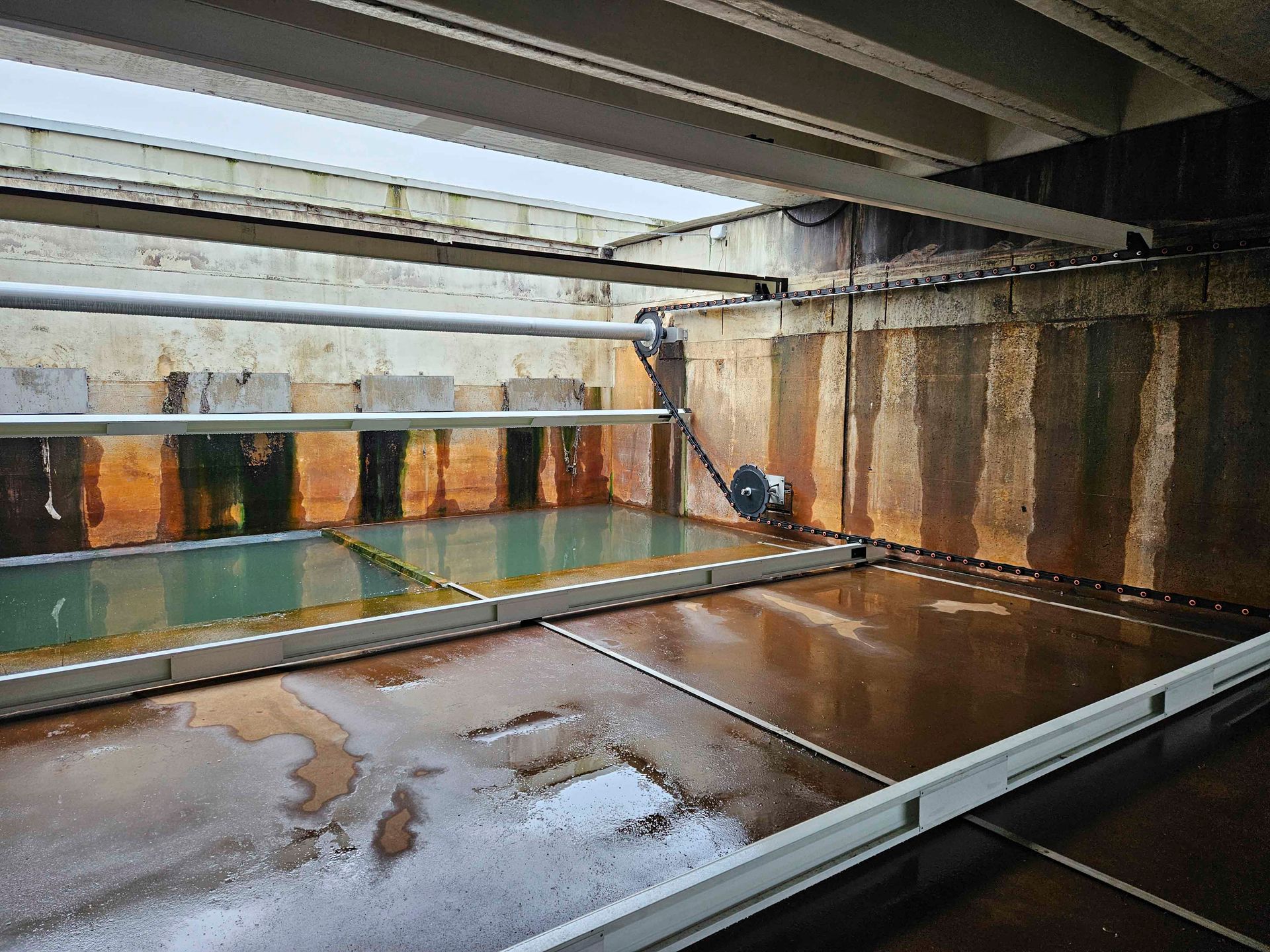

Waste water treatment plant Halle-North, Germany 2023

Primary clarifier: 40 x 8,4 m

1 DEWA® Plastic chain scraper system

In spring 2023, Hallesche Wasser und Stadtwirtschaft commissioned us to replace a chain scraper in the primary clarifier at the Halle-Nord sewage treatment plant. As part of the replacement, we dismantled the old steel chain scraper and installed a new DEWA® plastic chain scraper for continuous bottom and floating sludge removal. The tank is completely covered to contain the odour emissions, which is why the use of scraper bridges is not possible here. We are delighted to have another satisfied customer and are confident that we will also be able to renew the remaining primary clarifier scrapers in the coming years.

Secondary clarifier: 60 x 7 m

4 DEWA® Plastic chain scraper systems

In spring 2022, Stadtwerke Schramberg commissioned us to replace the old steel chain scrapers in the four secondary clarifiers at the Schramberg wastewater treatment plant with new DEWA® plastic chain scrapers. By the end of 2022, we had replaced all four scrapers and successfully put them into operation. The clear water drainage channels extend across the rear third of the tank with a scum pipe in front for floating sludge removal, which also serves as a baffle. In order to still be able to clear the entire pool floor, the scraper flights are deflected by a forced guide so that no collision with the effluent channels and the scum pipe is possible. The scraper flights are submerged just before the scum pipe and are guided on rails to the end of the tank, where they are deflected and clear the bottom sludge in the direction of the inlet-side sludge hopper.

Waste water treatment plant Schramberg, Germany 2022

Sewage treatment plant Winnweiler, Germany 2021

Grit and Grease trap: 15,4 x 5,20 m

1 Travelling bridge scraper

In summer 2020, we supplied a new longitudinal scraper bridge for the grit and grease trap at the Winnweiler sewage treatment plant. The half-wall bridge with railings is made of V2A stainless steel and all steel components that come into contact with wastewater are made of V4A. The longitudinal scraper runs on two galvanised rails and racks, one for each tank crown, and is driven by a gearwheel. The forced drive offers high operational reliability at all times of the year.

The grit is removed from the bottom of the grit chamber by means of a scraper blade into the hopper, from where it is conveyed to a grit classifier via a submersible motor pump. Clearing at the water surface of the grease trap chamber is carried out by the scraper blade, which pushes the grease into the sludge pit provided for this purpose via an approach ramp. To control the scraper bridge, there is a control cabinet with PLC and touch panel on the bridge, which is also made entirely of V2A stainless steel. The energy is supplied via motorised cable reel with slip ring assembly.

Secondary clarifier: 62 x 5,3 m

4 DEWA® Plastic chain scrapers with scum pipes

For the Goslar central sewage treatment plant in Thuringia in Germany, we were able to replace the old steel chain scrapers with our DEWA® plastic chain scrapers as part of the renewal of the scraper technology in all four secondary clarifiers. The low wear and tear and the enormous potential savings in maintenance and energy costs convinced the customer to opt for DEWA® plastic chain scrapers when renewing the scraper equipment. The DEWA® systems have been efficiently clearing the bottom and floating sludge in secondary clarifiers 1 & 2 since October 2021 and in tanks 3 & 4 since June 2022. The floating sludge is removed in all four tanks via scum pipes, which are operated manually using a hand crank.

Wastewater treatment plant Goslar, Germany 2021

Wastewater treatment plant Managua, Nicaragua, 2020

Primary clarifier: 22.5 x 7.25 m

18 DEWA® plastic chain scrapers with scum channels

Thanks to the Managua wastewater treatment plant in Nicaragua, the water quality of nearby Lake Managua, which was long regarded as the world's largest cesspit, has improved considerably. The plant treats around 140,000 cubic meters of wastewater every day. In 2020, we were able to supply a total of 18 DEWA® plastic chain scrapers for the nine primary clarifiers at the treatment plant via a German plant manufacturer that has gained a foothold in South America. To ensure the required settling surface, the tanks were equipped with lamella separators when they were first installed. The floating sludge that collects on the surface of the water between the effluent channels was not removed until the DEWA® systems were installed.

We supplied two floating sludge scrapers as 2-shaft systems and a floating sludge collection channel with a ramp for each primary clarifier. In order to be able to clear the floating sludge between the effluent channels, rigid metal shields with adjustable rubber scrapers were attached to the scraper flights at appropriate intervals, which continuously push the floating sludge towards the inlet. The floating sludge is skimmed off by a second scraper and conveyed into a collection channel via an approach ramp. Despite the coronavirus pandemic and with the active support of our customer, the scrapers were successfully put into operation in 2021, where they have been fulfilling their duties to the customer's satisfaction ever since.

Primary clarifier: 57 x 6 m and 60 x 5.6 m

8 DEWA® plastic chain scrapers plus fully automatic scum pipe

Oslo is one of the fastest growing cities in Europe. As part of the “UBRA” project (abbreviation for “Utbygging av Bekkelaget Renseanlegg”), which translates as the expansion of the Bekkelaget wastewater treatment plant, the wastewater treatment plant is being expanded underground from a capacity for around 270,000 PE to around 500,000 PE.

In spring 2019, we delivered the first four of a total of eight DEWA® plastic chain scrapers for unit 3. Four more systems for unit 4 with slightly different tank dimensions followed in summer 2019. Since the last commissioning in 2020, the low-wear DEWA® systems have been efficiently removing the floating and bottom sludge in all eight primary clarifiers. The floating sludge is removed fully automatically in all tanks using Actuator-controlled scum pipes.

Thanks to a newly developed process in which the scum pipe automatically adjusts to the changing water level, it is ensured that the scum is removed efficiently with a low water content even when the water level fluctuates.

Bekkelaget wastewater treatment plant (UBRA) Oslo – Norway, 2019

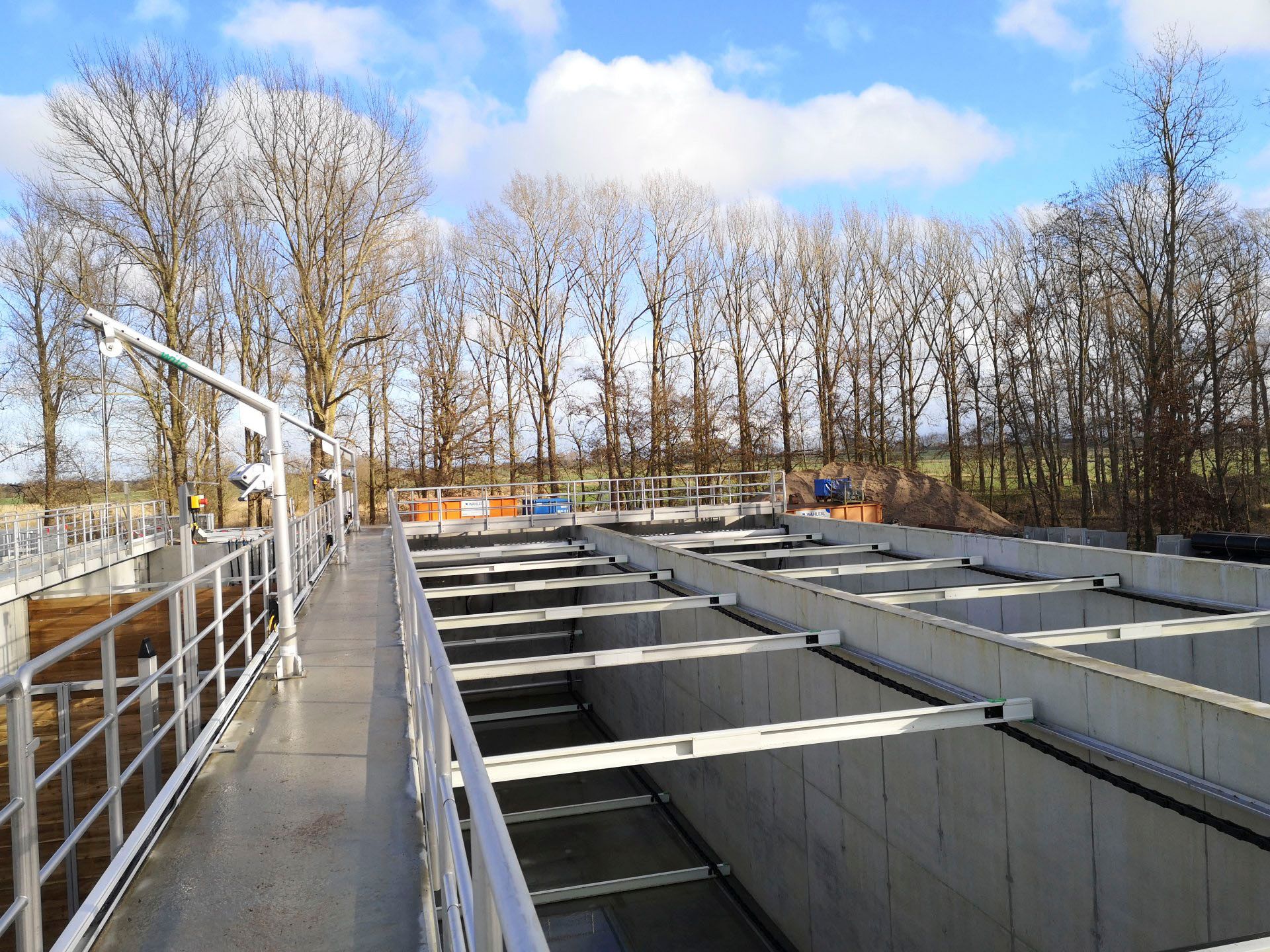

Cismar/Ostholstein Wastewater treatment plant , 2019

Primary clarifier: 25 x 4 m and secondary clarifier: 40 x 6 m

2 x 2 DEWA® plastic chain scrapers plus scum pipes

For the expansion of the Cismar sewage treatment plant (60,000 PE) in Grömitz Ostholstein, we delivered and installed a total of four DEWA® plastic chain scrapers. Since commissioning in February 2020, the extremely low-wear DEWA® systems have been clearing the floating and bottom sludge in the two new primary and secondary clarifiers. The floating sludge is removed in all basins by means of a scum pipe by manual operation.

Secondary clarifier: 23 x 11 m

1 DEWA® plastic chain scraper plus scum pipe

As part of the expansion of the wastewater treatment plant in Siegsdorf in summer 2019, we were able to equip the new rectangular secondary clarifier of the Bavarian mineral water supplier Adelholzener Alpenquellen with our DEWA® plastic chain scraper and two-part scum pipe. Despite the rather large basin width of 11 m, the DEWA® system has been reliably clearing the sedimented bottom sludge into the sludge hoppers provided for this purpose since it was commissioned at the end of 2019 and pushing the floating sludge towards the end of the basin, where it is completely removed via the two-part scum pipe with central support.

Adelholzener Alpenquellen wastewater treatment plant, 2019

Rastede wastewater treatment plant, 2018

Secondary clarifier: 40.6 x 6.5 m with bottom coves

1 DEWA® plastic chain scraper plus scum pipe and pipeline construction

In spring 2018, a longitudinal scraper bridge completed its last service in the rectangular secondary clarifier at the Rastede wastewater treatment plant. The low wear and tear and the enormous potential savings in maintenance and energy costs convinced the customer, to use a DEWA® plastic chain scraper when renewing the scraper system. To keep the downtime of the clarifier as short as possible, the replacement was completed by us within a very short time. In just two weeks we dismantled the old scraper bridge, installed the new DEWA® plastic chain scraper with scum pipe and installed a new pipe to carry the floating sludge from the new scum pipe (outlet side) into the existing pump pit for floating sludge (inlet side) within the basin. Commissioning took place immediately afterwards.

Primary clarifier: 50 x 10 m

12 DEWA® plastic chain scrapers plus maintenance platforms

In January 2015, we successfully commissioned the first two of a total of 12 DEWA® plastic chain scrapers at the Berlin-Wassmannsdorf sewage treatment plant. In September 2017, the last two systems were were put in operation and replaced the old steel chain scrapers. The low-wear DEWA® systems clear floating and bottom sludge in the primary clarifiers and in the centrate tank.

Berlin-Wassmannsdorf wastewater treatment plan, 2017

Oftringen wastewater treatment plant, Switzerland, 2017

Secondary clarifier: 44 x 8 m with bottom coves

8 DEWA® plastic chain scrapers with V-trough scum channel

In summer 2017, we have supplied the first two of a total of eight DEWA® plastic chain scrapers with V-trough scum channels for the secondary clarifiers at the Oftringen WWTP via our Swiss partner. The chain scrapers are being used to replace the old travelling scraper bridges. This will replace discontinuous sludge removal with continuous sludge removal.

The remaining systems were delivered in 2018 and 2019 and were also professionally installed and put into operation by our Swiss partner.

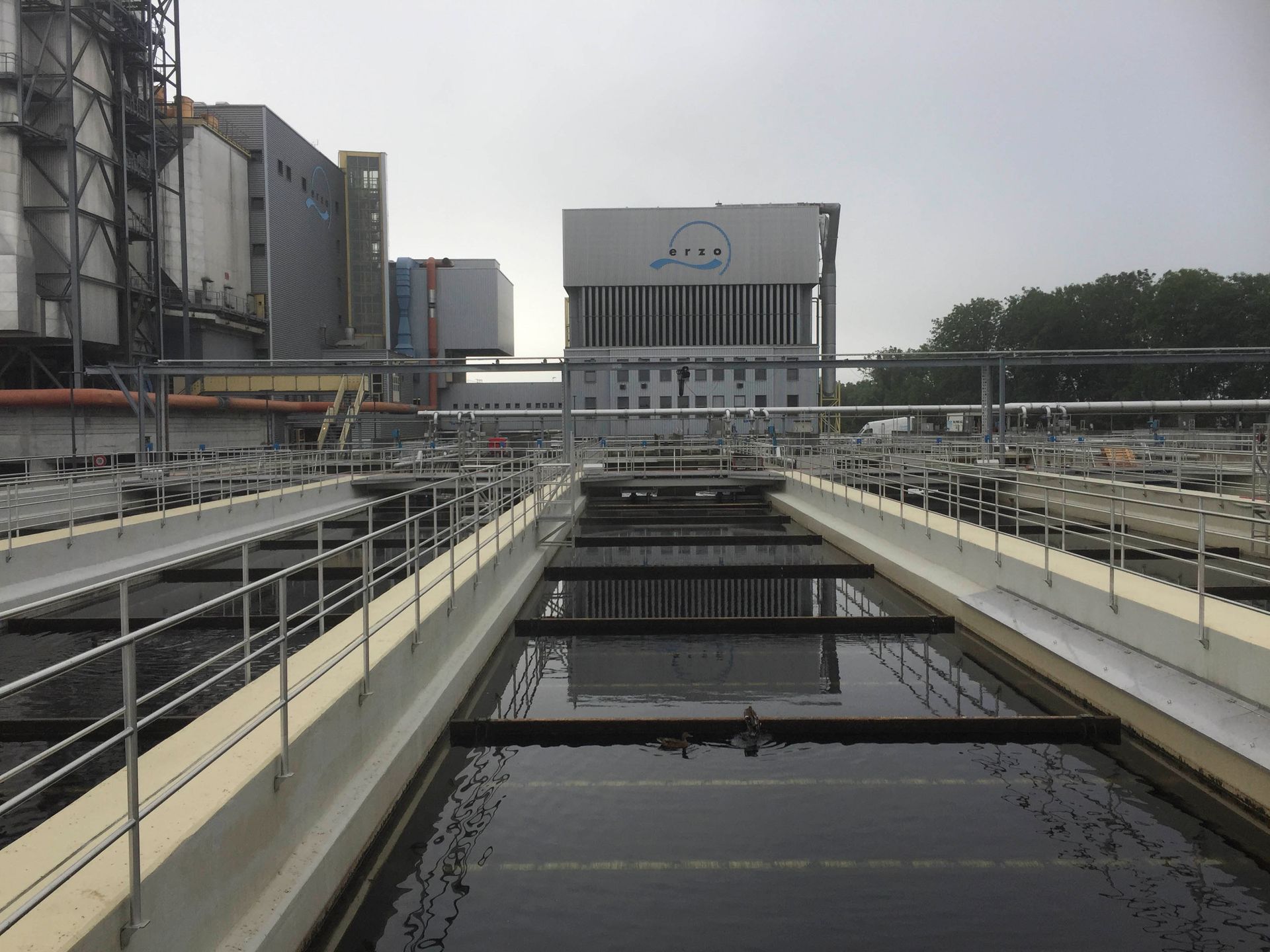

Mannheim sewage treatment plant / Post-treatment with powdered activated carbon (PAC), 2016

PAC settling tank, 77 x 6 m

10 DEWA® plastic chain scrapers as bottom scrapers plus inlet structures and scum pipes

In summer 2016, after the first 2 plastic chain scraper systems delivered in 2009, further 8 scraper systems went into operation. Now, 10 DEWA® bottom scrapers clear the powdered activated carbon sludge from the settling tanks to the sludge hoppers of the recirculation pumps and ensure perfect removal of trace substances at the Mannheim sewage treatment plant.

Settling tank: 40 x 12 m

20 DEWA® plastic chain scrapers

In winter 2012, we delivered a total of 20 DEWA® plastic chain scrapers to our French customer OTV, a subsidiary of Veolia Water Technologies, for the waterworks in Luanda, Angola. With the support of our supervisor, the installation of the DEWA® scrapers went smoothly the following year. The scrapers run as twin-shaft systems below lamella separators and reliably clear the sediment into the sludge hoppers provided for this purpose. Due to the basin width of 12 m, two chain scrapers were used for each basin. A total of ten identical sedimentation tanks were equipped with DEWA® plastic chain scrapers. The materials used are suitable for drinking water applications.