Flotation and sedimentation

For separating suspended (solid) substances, oils and fats from wastewater

Flotation and sedimentation units in stainless steel design are mainly used in industrial wastewater treatment and utilize the physical properties to separate unwanted substances from the water, sometimes with the addition of chemicals.

Flotation Unit (DAF)

Flotation is the floating of undissolved pollutants from the wastewater to the surface with the help of small air bubbles. The floated pollutants form a floating sludge which is removed from the flotation chamber using suitable scraper equipment.

The most economical process is dissolved air flotation (DAF), in which a partial flow of the clear water (recirculation flow) is saturated with air at overpressure and then fed into the flotation chamber via the dissolved air valves. After expansion, the excess air bubbles out in the form of fine air bubbles, which adhere to the sinking and floating dirt particles and sludge flakes as they rise and carry them to the water surface. The air bubbles form a layer of bubbles on the water surface before escaping. This has a high buoyancy force, which thickens the pollutants carried to the surface. The thickened floating sludge is removed via a scraper. The main area of application is the purification of floatable industrial wastewater, e.g. in slaughterhouses, meat processing plants, paper mills, dairies and breweries.

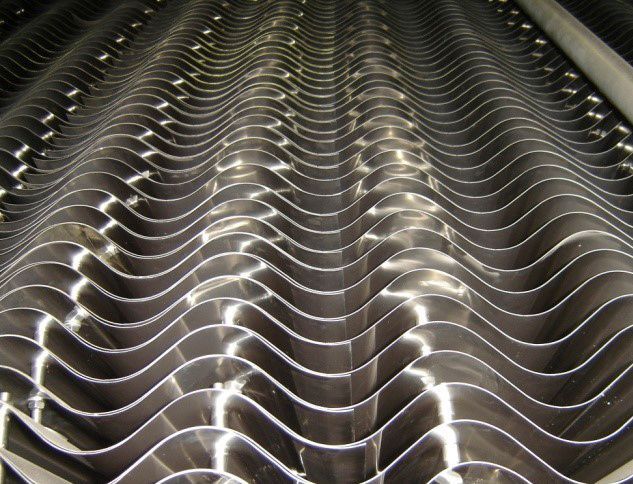

Sedimentation is of great importance in water technology, as it is often the simplest and most economical method for separating solid substances from the liquid phase. How well the solids are separated depends above all/among other things on the settling surface. If the local conditions require it, the specific surface area (m²/m³) can be increased by using lamella separators also called lamella settlers. These are parallel plates that are installed at an angle of between 45° and 60°. Compared to conventional systems, a 10 to 20-fold increase in surface area is achieved. The effect is that the sediments only have to sink through the small distance of a few centimeters between the plates instead of the entire depth of the tank in a sedimentation tank.

This results in a significantly better separation effect. The plates are inclined to allow the settled sludge to slide to the bottom of the tank. The systems are used for separating solids as well as fats/oils and are built to customer specifications. Depending on the application, counter-flow or cross-flow lamella packs made of stainless steel or plastic are used.